Limiting Damage to Flexible and Composite Pavements due to the Presence of Water: Guidelines (2025)

Chapter: 3 FINDINGS AND APPLICATIONS

CHAPTER 3—FINDINGS AND APPLICATIONS

OVERVIEW

The research aspect of this project involved a review of hundreds of references as well as a survey of state practices that address the issues of identifying and treating the effects of water on asphalt concrete and composite pavements. Accordingly, an initial primary finding is that there was more than enough information available to develop a single source resource document (the Guidelines document) that identifies the best practices for minimizing asphalt and composite pavement damage due to the presence of water. Additional products accompanying the Guidelines are a webinar to help promote the use of the Guidelines document, training course materials that demonstrate how the Guidelines document can be used for designing, building, maintaining, and rehabilitating asphalt concrete and composite pavements so that they are less susceptible to moisture damage, and a web-based computer application (DRAIN) to facilitate the use and application of the Guidelines. Following are summary descriptions of the products and findings of NCHRP Project 01-54.

SUMMARY OF GUIDELINES DOCUMENT

The Guidelines document includes seven main chapters (2 through 8) that describe the recommended key practices that can be used to help address (or minimize) moisture damage in asphalt concrete or composite pavements. A summary description of each of these key chapters is presented in the following sections.

Chapter 2—Determine the Source(s) of the Moisture

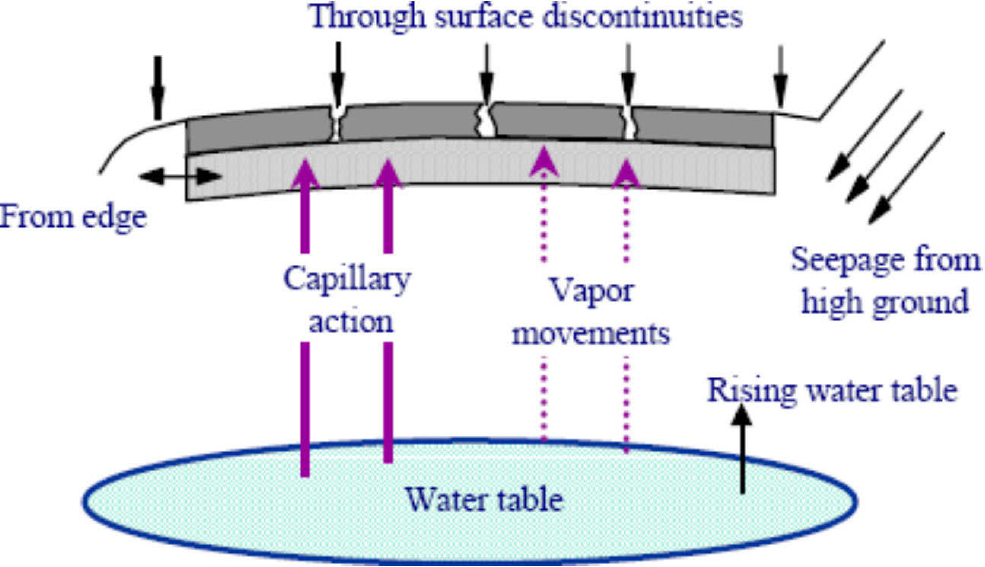

When addressing a moisture problem in an existing pavement (or when designing a new pavement to avoid moisture problems), it is important to identify the primary sources of moisture (see Figure 1). If these sources are not identified, then there is an increased risk that the treatment(s) selected will be ineffective or the new design will be inadequate. For example, if a chip seal is applied to an existing asphalt concrete pavement to help prevent surface moisture from infiltrating the pavement, but the primary source of the moisture is from capillary action, then the chip seal will not address the moisture problem and the pavement will likely experience accelerated deterioration because of the unchecked moisture from below and the potential for trapping subsurface moisture.

Chapter 2 defines the primary sources of moisture on a pavement structure, including surface infiltration, capillary action and vapor movement, changes in depth of the water table, seepage from high ground, and infiltration from the edge, and emphasizes the importance of correctly identifying moisture sources on a particular project. It also describes the mechanisms of moisture entry into the pavement structure for each of these sources.

Chapter 3—Identify the Key Mechanism(s) that are the Cause(s) of the Distress(es)

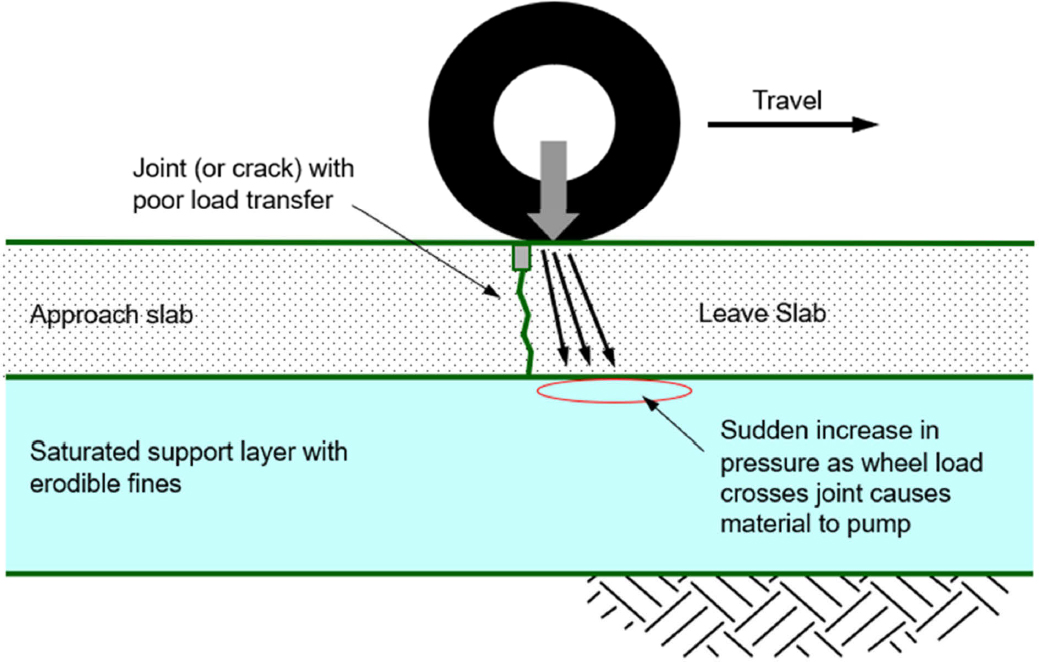

Along with determining the likely moisture sources for any given project, it is equally important to be able to identify the mechanisms by which moisture is contributing to pavement damage (for example, the pumping mechanism for concrete and composite pavements shown in Figure 2). Armed with this information, engineers and roadway designers can develop more effective design or treatment options that address both the distress and the underlying cause. As an example, when the designer understands that frost heave occurs in the winter as ice forms into wet, frost-susceptible soils, the designer can develop a treatment plan that can: 1) prevent moisture from entering the pavement, 2) reduce the depth of frost penetration, or 3) make the material less frost susceptible.

Chapter 3 provides basic descriptions for four different mechanisms that contribute to the different forms of moisture damage in an asphalt or composite pavement. These mechanisms include material softening/weakening, frost heave, asphalt stripping, and subsurface pumping. The chapter also provides a list of the common distress types associated with each mechanism.

Chapter 4—Consider Design Features

Chapter 4 identifies three main approaches for controlling or limiting moisture damage in pavements: 1) preventing moisture from entering the pavement system, 2) quickly removing moisture after it enters the system, and 3) using materials and design features that are insensitive to the effects of moisture. For each of these approaches, there is at least one design feature that should be considered when developing solutions to address the prevailing drainage problem. These features are described under four different categories as follows.

- Roadway geometric design—By determining the right combination of geometric factors (e.g., cross-slope, longitudinal slope, length of drainage path, and so on) for the pavement, shoulders, ditches, and curb and gutter, the pavement designer can come up with a geometric design for the pavement that minimizes the exposure of the pavement structure to moisture.

- Subsurface drainage design—A drainage system consisting of permeable layers, edge drains, underdrains, or horizontal drains, will help remove moisture entering the pavement from targeted sources before it significantly compromises the pavement structure (see Figure 3). Most of these features can be considered as part of the design for either a new pavement construction or reconstruction project. Retrofitted edge drains can be considered as an option for an existing pavement exhibiting moisture-related damage.

- Pavement (structural) design—To offset the weakening effect of prolonged moisture exposure in the pavement, it is often worth considering structural design alternatives that 1) increase the pavement’s load-carrying carrying capacity, 2) make the pavement more resistant to the presence of moisture, or 3) help prevent moisture from entering the pavement. The primary structural design option is subgrade stabilization, which can be achieved through mechanical means (such as adding or blending gravel and the use of geosynthetics), through the use of additives (such as portland cement, lime, and lime fly ash), or through a selection of a higher quality base material. Other specific design considerations for asphalt pavements, composite pavements, and pavement surface type (i.e., dense-graded asphalt concrete [AC], stone mastic asphalt, open-graded AC, and various surface treatments) are also included.

- Cold-climate design—Methods are identified to combat the negative effects of moisture and frost penetration in cold climates, i.e., frost heave in winter and high moisture in spring. The methods include removing frost-susceptible soils and replacing them with nonfrost-susceptible materials, stabilizing the subgrade soil, and increasing the structural capacity of the pavement.

Chapter 5—Consider Available Materials

Chapter 5 provides detailed guidance and information on the selection of paving materials associated with the various design features described in Chapter 4. These materials and their related characteristics should be thoroughly considered when trying to correct or limit moisture damage in a pavement. Under the heading of pavement structure, these include base materials

(unbound, aggregate separator, asphalt-treated, asphalt-treated permeable, cement-treated, and cement-treated permeable) and asphalt mixtures. In the category of geosynthetics, the primary materials are geotextiles and geocomposites (see Figure 4). Finally, for drainage systems, the key materials covered are trench backfill, drainpipe, outlet pipe, headwalls, and geotextiles.

Chapter 6—New Construction

The most cost-effective time to address the potential moisture issues in a pavement is in the design and construction stage. Accordingly, Chapter 6 provides guidance on three topics associated with new pavement construction. The bulk of the guidance is on the individual layers of the pavement:

- Subgrade soil treatment requirements (identification of weak areas, removal and replacement methods, stabilization methods, and dewatering systems). Figure 5 shows a rotary mixer used in a soil stabilization project.

- Base placement and compaction requirements.

- AC placement and compaction requirements.

- Concrete construction requirements.

- Construction quality control and acceptance.

Two additional topics are addressed in Chapter 6: the proper installation and construction monitoring of drainage systems and the basic design considerations for roadway widening.

Chapter 7—Maintenance and Preservation Strategies

Like other forms of pavement distress, the rate of damage associated with exposure to moisture can be significantly reduced by employing sound maintenance and preservation practices during the life of the pavement that will help keep water out. Chapter 7 addresses these practices from three different perspectives:

- Maintenance strategies—Patching and crack sealing/filling are the primary maintenance strategies used to address localized pavement distresses that can affect load-carrying capacity and ride quality, as well as moisture infiltration. Although these strategies are generally considered simple and straightforward, there are selection criteria, material considerations, and construction best practices that can improve their effectiveness and longevity.

- Preservation strategies—“Edge to edge” pavement surfacings or surface preservation treatments can help keep an existing pavement in good condition (see Table 2). In general, these treatments reduce the rate of age-hardening and improve surface friction. They also seal the pavement surface against moisture infiltration. Descriptive information and guidance are provided on seven types of surface preservation treatments appropriate for flexible and composite pavements, including scrub seals, chip seals, slurry seals, microsurfacing, cape seals, ultra-thin bonded wearing courses, and thin overlays.

- Drainage—When considering the maintenance needs of an existing pavement, it is also important to consider the maintenance needs of the pavement drainage features. For the purposes of the Guidelines document, they are discussed in terms of surface drainage, drainage ditches, and subsurface drainage.

| Treatments | Low Severity | Medium Severity | High Severity | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Low Extent | Moderate Extent | High Extent | Extreme Extent | Low Extent | Moderate Extent | High Extent | Extreme Extent | Low Extent | Moderate Extent | High Extent | Extreme Extent | |

| Recommended | ||||||||||||

| Crack Treating | Trans. Fatigue Block Edge Long. | Trans. Fatigue Block Edge Long. | Fatigue Edge Long. | Fatigue Edge Long. | Trans. Block Edge Long. | Trans. Block Edge Long. | Edge | Edge | ||||

| Crack Leveling | Fatigue Edge Long. | Fatigue Edge Long. | Fatigue Edge Long. | Fatigue Edge Long. | Edge Long. | Edge Long. | Trans. Edge Long. | Trans. Edge Long. | Long. | Long. | ||

| Route and Seal Cracks | Trans. Fatigue Block | Trans. Fatigue Block | Fatigue | Fatigue | Trans. Block | Trans. Block | ||||||

| Fog Seal* | Fatigue Block | Fatigue Block | Fatigue | Fatigue | ||||||||

| Rejuvenating Seal* | Fatigue Block | Fatigue Block | Fatigue | Fatigue | Block | Block | ||||||

| Chip Seal* | Trans. Fatigue | Trans. Fatigue | Trans. Fatigue | Trans. Fatigue | Edge Long. | Edge | Long. | Edge Long. | Edge Long. | |||

| Scrub Seal* | Trans. Block | Trans. Block | Block Edge Long. | Block Edge Long. | Block | Trans. Long. | Edge Long. | Edge Long. | ||||

| Microsurfacing* | Trans. | Trans. | Trans. | Trans. | ||||||||

| Cape Seal* | Long. | Edge | Edge | |||||||||

| Cold Milling* | Fatigue | Fatigue Block | Fatigue Block | Fatigue Block | ||||||||

| Thin HMA Overlay* | Block | Block | Trans. | Trans. | Fatigue Block | Fatigue Block | Trans. Fatigue Block | Trans. Fatigue Block | ||||

| Cold In-Place Recycling* | Trans. Fatigue | Trans. Fatigue Block | Block | Trans. Fatigue Block | Trans. Fatigue Block | |||||||

| Feasible | ||||||||||||

| Crack Treating | Trans. | Fatigue | Fatigue | Trans. Block | ||||||||

| Crack Leveling | Trans. Fatigue | Trans. Fatigue | Trans. | |||||||||

| Route and Seal Cracks | Edge | Edge | Trans. | Fatigue Edge | Fatigue Edge | Trans. Block Edge Long. | Edge Long. | Long. | Long. | |||

| Spray Patching | Fatigue | Trans. Fatigue | Trans. | Trans. | Trans. Fatigue Block | Trans. Fatigue | Trans. Fatigue | Trans. Fatigue | ||||

| Micro-Milling | Trans. | Block | Block | Trans. | ||||||||

| Fog Seal* | Trans. | Trans. | Trans. | |||||||||

| Rejuvenating Seal* | Trans. | Trans. | Trans. | Trans. | Trans. | |||||||

| Chip Seal* | Block Edge Long. | Block Edge Long. | Block | Block | Trans. Fatigue Block Edge | Trans. Fatigue Block Edge | Trans. Block | Trans. Block | Edge | Edge | ||

| Scrub Seal* | Fatigue | Fatigue Long. | Fatigue Long. | Fatigue Block Long. | Fatigue Block Long. | |||||||

| Slurry Seal* | Fatigue Block Long. | Block Long. | Block Long. | Block Long. | Trans. Block Long. | Long. | Long. | Long. | ||||

| Microsurfacing* | Fatigue Block | Block | Block | Block | Trans. Fatigue | Trans. Fatigue | Trans. Long. | Trans. Long. | Trans. | |||

| Cape Seal* | Fatigue Edge | Edge | Edge | Edge | Long. | Edge | Edge | |||||

| Cold Milling* | Fatigue | Fatigue | Trans. | Trans. | Trans. | |||||||

| Thin HMA Overlay* | Fatigue | Block | Trans. Block | Fatigue Block | Fatigue Block | |||||||

| Bonded Wearing Course* | Fatigue | |||||||||||

| Cold In-Place Recycling* | Fatigue | Trans. | Block | Block | Block | |||||||

| Patching | Edge | Edge | Edge | Edge | Edge | Edge | ||||||

*Consider prior treatments

Chapter 8—Rehabilitation Treatments

The selection of the right treatment for a rehabilitation project is much simpler than addressing drainage in new design. This is because most of the moisture damage problems will already be manifesting themselves as various forms of distress that can be identified and corrected. Chapter 8 provides rehabilitation recommendations to address the needs of both existing pavements and existing drainage systems. For pavements, guidance is provided in the form of: a) rehabilitation treatment selection based on the observed types of distress (see Table 3), b) pretreatment application requirements, c) techniques to address reflection cracking, and d) construction considerations. For drainage systems, recommendations are offered primarily for: a) a stepwise process to assess the needs, and b) the design and construction of retrofitted edge drains. Other parts cover shoulder reconstruction, new or replacement drainage systems, and overall construction considerations.

| Distress | Asphalt Overlay | Concrete Overlay | Reconstruction |

|---|---|---|---|

| Fatigue cracking | ✓ | ✓ | ✓ |

| Block cracking | ✓ | ✓ | ✓ |

| Thermal cracking | ✓ | ✓ | ✓ |

| Slippage cracking | ✓ | ✓ | NA |

| Bleeding | ✓ | ✓ | NA |

| Rutting | ✓ | ✓ | NA |

| Shoving | NA | ✓ | ✓ |

| Weathering | ✓ | ✓ | NA |

| Raveling | ✓ | NA | NA |

| Stripping | ✓ | NA | ✓ |

| Potholes | NA | NA | ✓ |

| Bumps, settlements, heaves | ✓ | ✓ | ✓ |

| Typical Range in Service Life (years) | 8 – 15 | 20 – 30 | 15 – 25 (asphalt) 20 – 30 (concrete) |

OTHER KEY PROJECT DELIVERABLES

Webinar

A 90-minute webinar was developed to help introduce and promote the use of the Guidelines document.

Training Course

A 1-day training course was developed as a resource to provide training on the use of both the Guidelines document and the associate web-based application tool (DRAIN). The key components of the training course are the PowerPoint presentations, the Instructor Guide, and the Participant Workbook. The training course has been developed such that it could be incorporated into the training curriculum on the NHI. The proposed agenda for the training course is shown in Table 4.

Table 4. Agenda for 1-day training course.

| Title | Duration (min) | Possible Schedule |

|---|---|---|

| Module 1 Introduction | 25 | 8:00–8:25 a.m. |

| Module 2 Sources of Water and Distress Mechanisms | 41 | 8:25–9:06 a.m. |

| Break | 15 | 9:06–9:21 a.m. |

| Module 3 Design Features | 67 | 9:21–10:28 a.m. |

| Module 4 Material Type and Selection | 40 | 10:28–11:08 p.m. |

| Lunch | 60 | 11:08–12:08 p.m. |

| Module 5 New Construction | 69 | 12:08–1:17 p.m. |

| Module 6 Maintenance and Preservation Strategies | 55 | 1:17–2:12 p.m. |

| Break | 15 | 2:12–2:27 p.m. |

| Module 7 Rehabilitation Treatments | 47 | 2:27–3:14 p.m. |

| Module 8 DRAIN Tool | 40 | 3:14–3:54 p.m. |

DRAIN Tool

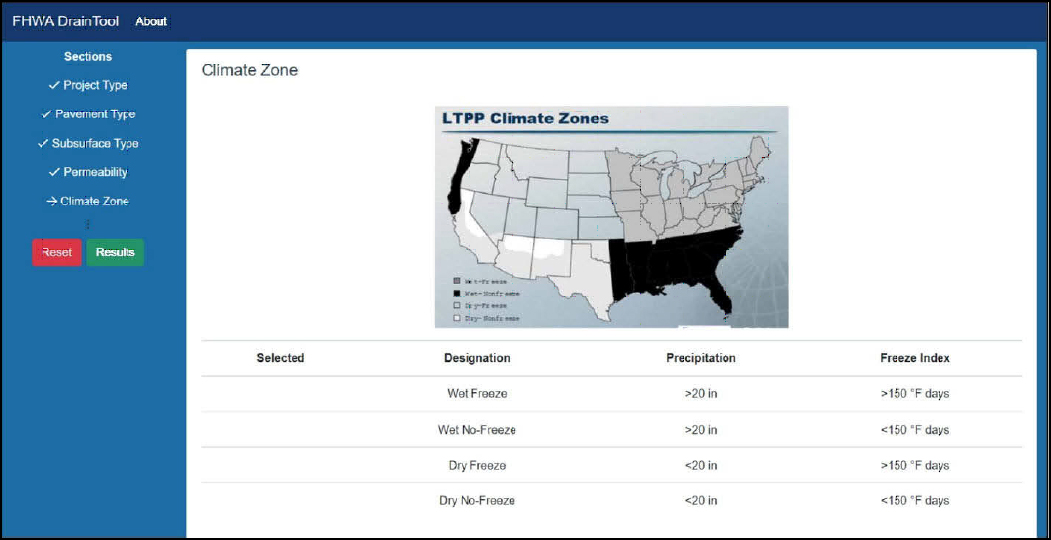

The DRAIN tool is a web-based application that allows users to enter information about a given project and access information within the Guidelines document to help address a moisture problem in an AC or composite pavement. In other words, DRAIN provides a programmatic interface to the Guidelines document, directing the user to the methods applicable for the pavement they are designing or maintaining. DRAIN is available on the National Academies Press website (nap.nationalacademies.org) by searching for NCHRP Web-Only Document 433: Limiting Damage to Flexible and Composite Pavements Due to the Presence of Water: Guidelines. The tool can operate on almost any platform, ranging from a mobile phone to a desktop computer. Figure 6 illustrates an example data entry screen in DRAIN.

SUMMARY

With the increasing emphasis on improving pavement engineering practices to get the most out of taxpayer dollars, NCHRP Project 01-54 is a timely study. By developing the comprehensive Guidelines document and incorporating the approaches into standard practice, this NCHRP project provides the tools that highway agencies and public works departments need to better address moisture problems in their pavements and realize better performing, longer lasting pavements.